CM Venture Capital led the investment in a ten million yuan angel round of financing by Tetrels. This round of financing is mainly used for Tetrels’s domestic construction of R&D laboratories, pilot production lines, and water treatment prototype projects.

Tetrels was established in New Jersey in the United States at the beginning of 2017. It is committed to using new nanomaterials to develop a new generation of water treatment membrane products, including ultrafiltration membranes, nanofiltration membranes, and reverse osmosis membranes for sewage treatment and seawater desalination. The company headquarters and R&D center will be established in Shanghai in September 2020 to focus on exploring the Chinese market and the global market.

Dr. Kunzhou Li, the founder of Tetrels, has spent many years in research and development at Seoul National University in South Korea. In response to the “pain points” of low water flux, fouling intolerance, and high maintenance costs of existing water treatment membrane products, he successfully developed a two-dimensional functionalized nano-graphene composite Materials and structures have greatly improved the performance of a variety of water treatment membrane products.

Dr. Li believes: “The Chinese water treatment membrane market has soared from less than 200 million yuan in the 1990s to the current scale of over 200 billion yuan. It is conservatively estimated that the market size will stably exceed 300 billion yuan by 2025. Although the market scale is developing rapidly in China, due to the development history of domestic membrane technology is less than ten years, the hollow fiber membranes are easy to fracture and the filtration layer is easy to fall off from the surface of the support layer, etc. those problems have been solved more than ten years ago by foreign head membrane companies, domestic membrane companies have only initially found the solution in recent five years. and for the problems of low water flux and fouling easily, breakthrough technological progress has not yet been made. Although many cutting-edge scientific research technologies can greatly improve the performance of existing membrane products, they cannot be applied, mainly because there are three barriers: first is the lacks of the verification of cutting-edge new technology in practical engineering application; the second is the lacks of the stabilize mass production technology of the new technology and new process, and the R&D investment of mass production technology is not enough; the third is the R&D department of the membrane companies has inertial thinking and less understanding of the latest nanotechnology and other related new technologies.”

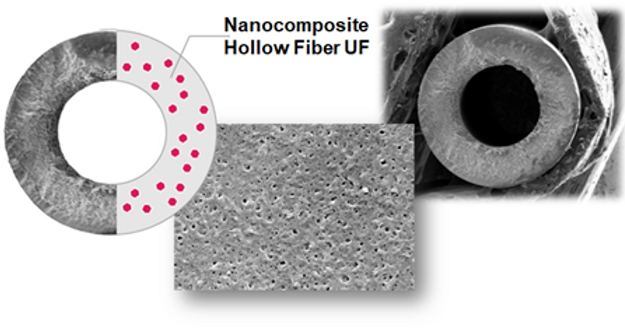

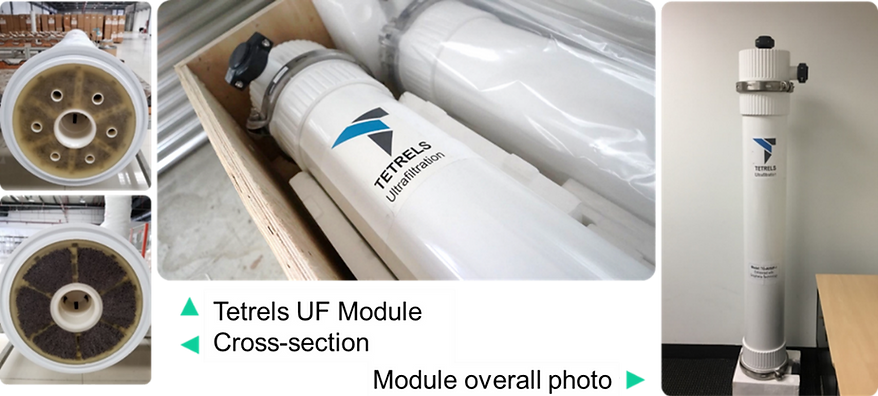

In order to promote environmental protection, energy-saving, and emission reduction, and to make new technologies work, Dr. Li puts his own technical formula into OEM trial production and promotes the verification of practical engineering applications. On the other hand, he increases the research and development of mass production technology and processes. At the end of 2017, Tetrels invested in the Advanced Aerospace System Lab of Seoul National University, increased R&D investment and bought out the research and development results of the institute, and successfully completed the trial production of the first product in 2018 —— Organic-inorganic hybrid nanocomposite hollow fiber ultrafiltration membrane (module). At the beginning of 2019, Tetrels realized small-scale mass production of this nanocomposite hollow fiber ultrafiltration membrane and accumulated more than one year of engineering application tests in two practical water treatment projects. The results prove that compared with other commercial ultrafiltration membranes, the pollution resistance of Tetrels products is greatly enhanced, the cleaning and maintenance cycle is extended by 2-3 times, and the membrane lifetimes is extended by more than 2 times; the water flux is improved 20% compared with international mainstream brands at least. In the mid- 2019, the mass production technology and process development of the specially-made functionalized nanographene were also successfully completed, hence the manufacturing cost of membrane products using new nanomaterials would not be increased significantly. In this way, Tetrels’ ultrafiltration membrane products can save a lot of maintenance costs and consumables costs for downstream water treatment projects, and the energy efficiency of the water treatment system would increase consequently.

Prior to this, the world’s leading water treatment companies tested Tetrels’ samples and evaluated this product as the best domestic ultrafiltration membrane in China. Currently, the two parties are actively promoting follow-up technical and production cooperation. At the same time, the company’s products have also been favored by the domestic market and are negotiating cooperation with many domestic engineering companies.

CM Venture Capital has long been concerned about supporting green and sustainable development from the perspective of new materials. The global membrane industry is a huge market of hundreds of billions of dollars, and traditional organic membranes, as the main force of membrane consumables, have been criticized for being vulnerable to pollution and high maintenance costs, and there is a huge market development space. We look forward to Tetrels starting from membrane technology research and development, with membrane consumables sales as the fulcrum, leveraging the huge market of water treatment projects represented by MBR in China, and planning for the United Nations Sustainable Development Goals for clean drinking water and China’s carbon-neutral environmental protection plan, China’s “14th Five-Year Plan” to promote green and low-carbon development to do its part.