We’re excited to announce a new entrant into our Fund III portfolio: Shenzhen Sengong New Material Technology, a startup that’s innovating the production and widespread use of PVA material (Polyvinyl Alcohol). PVA isn’t new, but it hasn’t been widely adopted due to cost challenges or limited functionality.

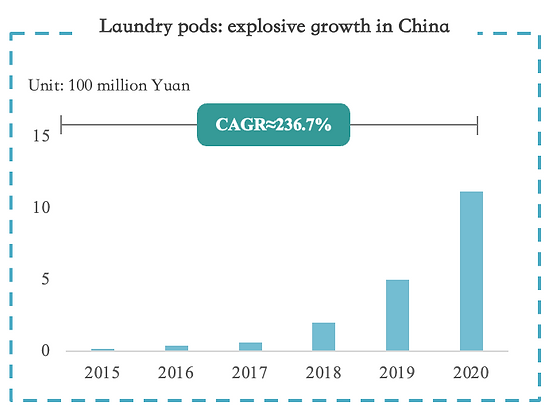

Primarily, PVA is an FDA-approved non-toxic, odorless and colorless synthetic plastic polymer safe for use in pharmaceutical and food industries. It’s commonly integrated with daily household products: laundry pods, single-use plastic wraps or water-soluble laundry bgs. For the US, detergent packaging (laundry pods) was the dominant segment for PVA use in 2020, with a market share of over 37%. Water-soluble detergent packaging in China is catching up fast, with the volume doubling in 2022, compared to 2021.

Based in China, Sengong has innovated a production method which drops the cost of PVA by as much as 40%, making it almost as affordable as conventional PET plastic. Uniquely, Sengong’s PVA can be re-used up to 50 times, which helps drive the cost of PVA use even lower – not to mention, making it environmentally friendly at the same time.

Sengong’s raw materials are sourced locally. While other PVA films rely on chemically-modified PVA resins, Sengong’s mix uses additives to physically strengthen the PVA resin, to formulate a solidity content of up to 50% (compared to about 20% in common PVA films). The batch is drawn to form a continuous sheet, which is then placed on a stainless steel belt to be dried. . Infrared heating, combined with a steam heating process, help to cut production energy costs by as much as 50%. This makes Sengong’s production process extremely unique. And that is why it’s able to deliver superior quality PVA films at a lower cost and in higher volumes.

Using steam as a heat source also means Sengong’s PVA production line is also eco-friendly as well. As much as 75% of their overall energy needs comes from steam power, meaning their production facility needs far less electricity than conventional PVA film factories – many of which traditionally require massive electrical energy to power their heating elements to dry out the PVA films during production.

A unique steam process helps save massive energy bills

Beyond detergent pods, Sengong has developed proprietary formulations tuned for a variety of applications, to enable a circular economy through re-usable PVA. For example, instead of using PET as a substrate for PVD, PVA makes the perfect stand-in substrate for PVD. Using water-expandable PVA cuts out the need for adhesives applied to PET substrates in the process. It also eliminates the need for the toxic solvents to remove the adhesives later. At the end of the process, the PVA can simply be peeled off through water immersion. And the best part? The used PVA material can be re-processed for up to 50 cycles.

Another Sengong formulation is applied in packaging for logistics, where the packaging can be re-used multiple times. Its biodegradable, non-toxic properties could also benefit the food delivery industry, which is known for its reliance on single-use plastics. The farming industry could rely more on PVA, rather than PET, to deliver nutrients or insecticides with no harmful remnants left behind. For the health industry, water-soluble PVA laundry bags can contain soiled gowns to prevent contamination and disease until it’s exposed to water in the washing machine. Once the wash cycle completes, out comes clean gowns and clothes, less the laundry bag.

Currently, PET plastic is applied for the industries mentioned above because it’s cheaper. By making PVA at nearly the same cost of PET, a much higher adoption rate is expected. This leads to less use of non-recyclable plastic across industries. In turn, this supports mankind’s drive to create a more sustainable environment to help with world climate issues.

And where did it start? The founders of Sengong come from a heritage of chemical engineering and trading experience. With unique market insights, equipment know-how and a global mindset, founder Wang Mingzhe started by researching the microplastics issue with the planet. The Great Pacific Garbage Patch was a point of focus, but trying to find a way to clean up the country-sized patch was extremely challenging – and effects may be minimal. Yet since plastic is so central to our daily lives, Mr Wang decided to help through making biodegradable plastic easily accessible to more. And the answer was to create an affordable, eco-friendly, high-performance PVA that can be re-used multiple times.

Today, Sengong is a leading player in a material category which we believe will grow. With a strong cost advantage, proprietary technology, and an environmentally friendly nature, it’s certainly poised to be a game changer in the plastics sector.