Stephane Vernede, CEO and Co-founder of Enwise

China enters the era of waste sorting and the proper processing of wet waste is crucial. When wet waste is separated and properly processed all other waste become easy to handle, store and process.

Processing wet waste uses a natural and fundamental process: Digestion. This process is used by living forms to recover energy by transforming complex organic matter to simple mineral matter. Technologies to process wet waste uses this natural process while ensuring that it occurs in optimal conditions. The output is a fertilizer containing the mineral matter and sometime energy.

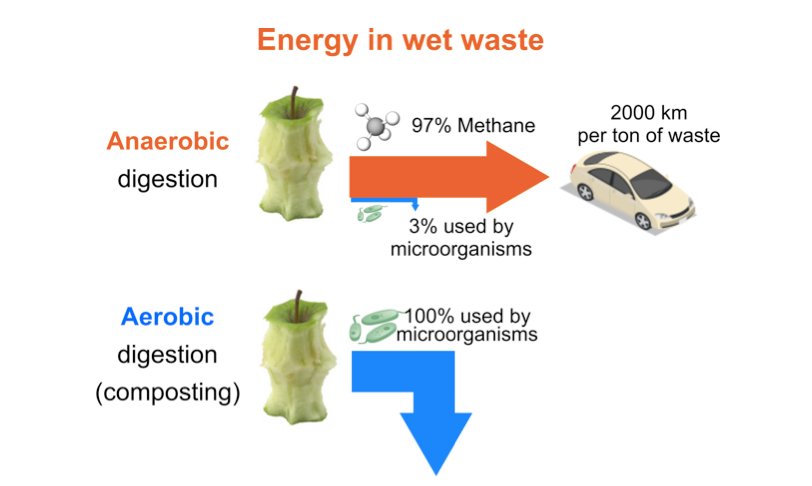

Two processes are available for digestion: anaerobic digestion and aerobic digestion, the latter being also known as composting. When you do sport, you can train anaerobic exercises, such as weight lifting, where your muscle operates without supply of oxygen. You can also train aerobic exercises, such as jogging, where oxygen is continuously supplied to your muscles. Similarly, microorganism can operate without oxygen or with oxygen when they digest wet waste. This is called anaerobic and aerobic digestion respectively.

Oxygen is a powerful oxidizer. Without oxygen, microorganism can only recover 3% of the energy present in the waste. But there is good news, those microorganisms make the remaining 97% of the energy available to us in the form of methane, the main constituent of natural gas. The amount of energy we recover from anaerobic digestion is significant. A ton of wet waste produces 80 cubic meters of methane, which can fuel a car for 2000 km. With oxygen the microorganisms can recover all the energy in the waste and left nothing to us. This is summarized in the graph below.

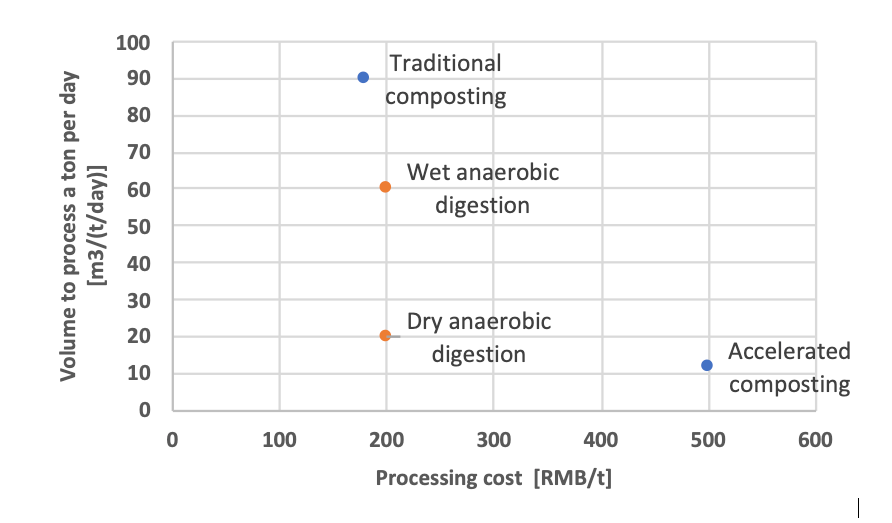

Digestion technologies are separated in four categories, two anaerobic digestion technologies, traditional wet anaerobic digestion, and dry anaerobic digestion and two aerobic technologies, traditional composting and accelerated composting.

We have limited land and resources to process wet waste. We therefore compare the different technologies based on the cost for processing wet waste, including operation costs and equipment depreciation, and the digestion volume required to process a ton per day.

Dry anaerobic digestion is an attractive technology to process wet waste with both low processing cost and land requirements. Being an anaerobic technology, dry anaerobic digestion has optimal energy recovery. Traditional composting is a slow process and requires a large amount of land to operate. This make this technology not suitable in densely populated area. Accelerated composting requires a large amount of energy to heat up and dry the wet waste. The operation costs of accelerated composting are therefore very high. Also, as the processing time is too short to ensure a proper digestion of the organic matter to mineral mater, the output of fast composting is not suitable to be directly used as a fertilizer. Wet anaerobic digestion has a processing cost close to dry anaerobic digestion but requires much more space to operate.

Processing wet waste is only one part of the problem. Sorting and transporting waste accounts for over 60% of the total waste disposal cost. To reduce those costs waste processing shall be done locally, as close as possible to the place where waste is generated.

Enwise proposes a wide range of wet waste processing module with processing capacity ranging from 500 kg/day to 30t/day. This allows select the right size to minimize transport cost given the local situation. Our modules are remotely controlled and uses a high efficiency dry anaerobic digestion technology, providing low processing cost and optimal resource recovery. We hope that our technology will contribute to find an efficient and environmentally friendly way to process wet waste in China.