Every undergraduate majoring in ceramics learns quickly that the Achilles’ heel of ceramics is its brittleness. Unlike metals that are ductile and workable, ceramics is difficult to shape by machining. I did my Ph.D. in “superplasticity of ceramics”, which aimed to create ceramics that are “super-plastic” compared to normal ceramics. But even superplastic ceramics can only be shaped at very high temperature and the shaped object end with plenty of porosity, which reduces its strength. Without efficient way of making complex shapes and structures, technical ceramics is severely limited in its use.

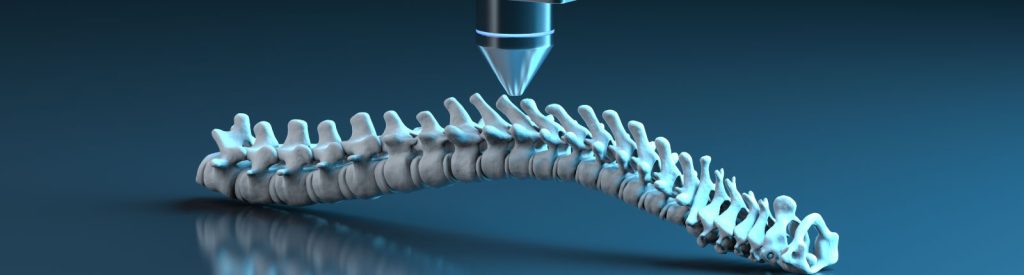

Precisely because ceramics is so difficult to shape, the fast-growing 3D printing technology has potential to make a difference. 3D printing, for the first time, allows ceramic powders to be deposited precisely where they need to be, with the aid of a photopolymer or a binder. The photopolymer or binder is burned out in subsequent sintering, so some shrinkage is inevitable.

As with all 3D printing technologies, 3D printing of ceramics is not a panacea suited for every fabrication of technical ceramic objects. We think the fabrication technique is particularly suited for:

Making high precision, high value technical ceramic objects in 3D printing is a multidisciplinary effort:

With the challenges of making good 3D printing products and identifying good applications, there are far fewer 3D printing companies in the ceramics field compared to 3D printing of resins, filaments or metal. A good overview of the current 3D printers of ceramics can be found at https://all3dp.com/1/3d-printing-ceramic-3d-printer/.

If you are working on developing world-class ceramics 3D printing technologies (equipment + software + material), we would love to hear from you!